The quality of the silicon wafer is essential for the production of highly efficiency solar cells. Due to the higher tolerance to impurities as well as the lack of light-induced degradation (LID), In the current market scenario the highest solar cell efficiency has been achieved in n-type silicon (in the lab as well as in production) base material. Despite these factors, p-type silicon remains the material of choice for the photovoltaic industry. An important reason for this is to be found in the solidification of silicon from its molten state. Boron has a segregation coefficient close to 1, which results in a small variation of its concentration along the silicon ingot and a relatively tight distribution of wafer resistivity. In contrast, phosphorus has a low segregation coefficient that results in a strong variation of wafer resistivity along the ingot which is an obstacle for industrial processes and device designs with tight wafer resistivity specifications.

N-type solar cells are based on n-type silicon wafers which are produced differently in the doping process during crystallization: while for p-type silicon usually employs boron as a dopant, n-type silicon crystals, usually phosphorus is added to the silicon melt. N-type solar cells feature two important advantages: they do not suffer from light induced degradation (LID) and they are less sensitive to impurities that are usually present in silicon feed stock.

Appearance

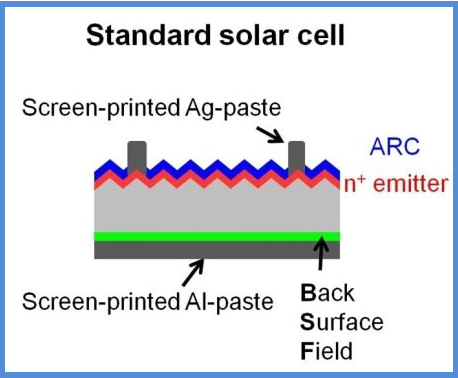

Standard Solar Cell

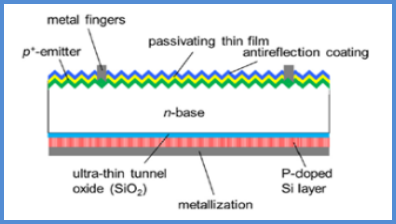

TOPcon Solar Cell

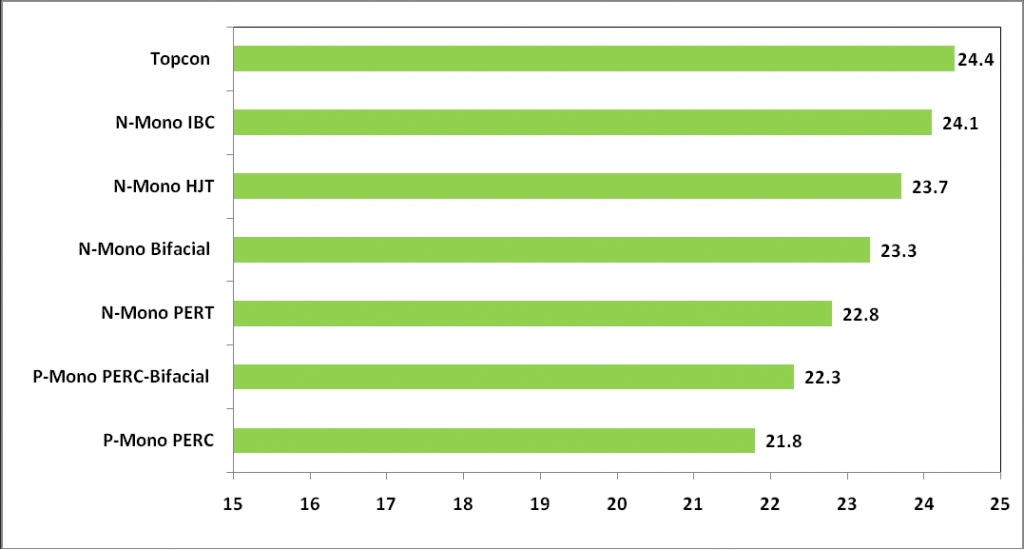

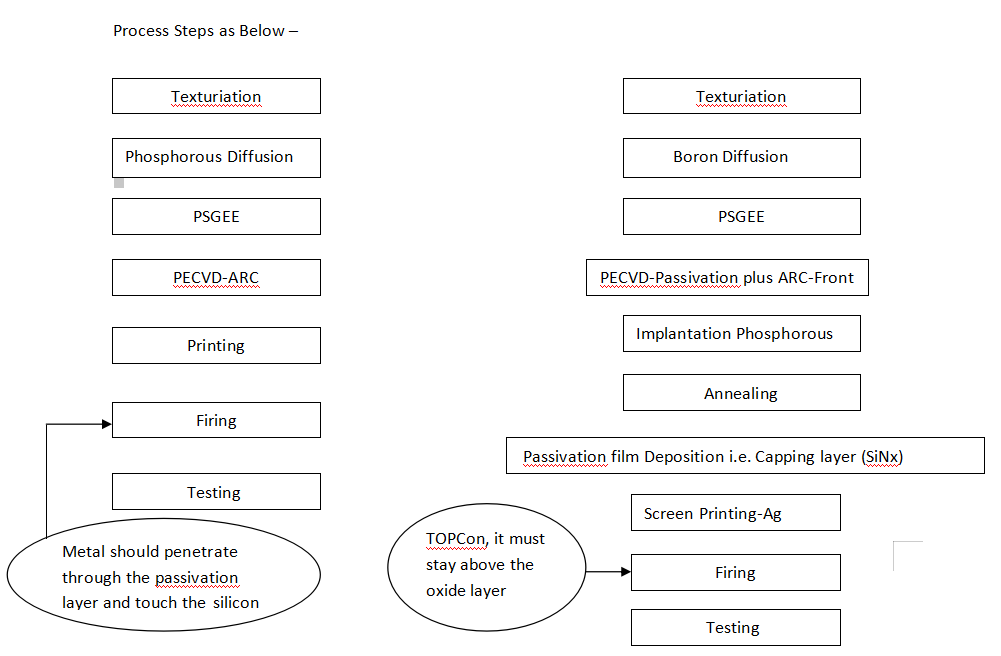

N-Mono technologies (N-PERT, IBC & TOPCon) are the next up gradation in PV technologies to take the efficiency further up. P-mono cell pants are easily up gradable to N-mono technologies by addition of certain equipment. Also the N-type material is less prone to LID which means the module can give +87% power by end of 30 years. TOPCon cell technology has become one of the two leading next-generation options after mono PERC. TOPCon- Tunnel oxide passivated contacts (TOPCon Solar Cells) are based on an ultra thin tunnel oxide capped by a doped Si film exhibiting excellent passivization and contact properties. So, this will lower the contact resistance higher fill factor, overall Eff. will improve From 24.1 to 21.8 %. For the concept, in order to reduce recombination losses from the metal contacts and the silicon surface of cells, a thin oxide layer is introduced, in addition to heavily doped poly crystalline silicon between metal contacts and wafer.The charge carriers, i.e. electrons and holes, can tunnel through, due to a quantum-physical phenomena. This establishes the contact, while the wafer is better passivated, and recombination losses are significantly reduced compared to standard technology. Diagram and Process steps are mentioned as below –

Comparison between Standard solar cell and TOPcon Solar Cells

| Parameter | Standard Solar Cells | TOPcon Solar Cells |

| Voc | 639.4 ± 2.0 mV | 700.8 ± 3.5 mV |

| Isc | 8.95 ± 0.12 A | 9.816 ± 0.093 A |

| FF | 80.32 ± 0.49 % | 83.00 ± 0.91 % |

| Power | 4.598± 0.070 W | 5.71 ± 0.074 W |

| Efficiency | 18.64 ± 0.29 % | 23.19 ± 0.32 % |

| Temp Coeff. | -0.38 % / K | -0.32 %/ k |

Lower Temp. Coefficient observed in TOPCon solar cells means when temperature increase power output of the TOPCon solar panel decrease less as compared to standard solar based solar panel.

Note – TOPCon solar cell can be made based on P-type or N-Type silicon material but because carrier issue N-Type have better performance. Now we can say TOPCon is popular in N-Type based material.

Good Article…Very Informative..